Concrete Mould for Making Hollow Blocks Solid Bricks Paving Stone Curbstone

Concrete Mould for making hollow blocks solid bricks paving stone curbstoneHawen moulds have been widely used in the mar

Description

Basic Info.

| Mould Surface Strength | HRC61 |

| Tamper Head | 16# Manganese Steel |

| Life Span | 100, 000 ~120, 000 Cycles |

| Mould Core Strength | HRC33 |

| Heat Treatment | Carburizing, Nitriding and Quenching |

| Mould Frame | 55# Manganese Steel |

| Fabrication Way of Mould Shoe | Wire Cutting by CNC Machine |

| Surface Hardness | HRC58-62 After Heat Treatment |

| Transport Package | Standard Ocean Packing |

| Specification | Customized |

| Trademark | HAWEN |

| Origin | Quanzhou City, Fujian, China |

| HS Code | 84748090 |

| Production Capacity | 1000sets/Year |

Product Description

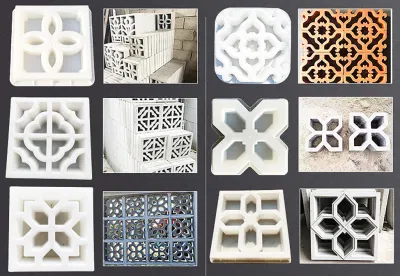

Concrete Mould for making hollow blocks solid bricks paving stone curbstoneHawen moulds have been widely used in the market for several of years.Our moulds extensive use of special alloys, tight manufacturing tolerances, and the gap between the upper and lower sides of the mold is reasonable through a wire cutting process, with a gap of 0.8-1mm. Material hardening heat treatment and other processes such as oil quenching, set our molds apart from others in the industry.Unique mold accessories like horizontal core pullers, electrically heated demolding shoes and movable component molds are all available from us.Our molds are innovative, versatile, and capable of making the highest quality concrete products.We can also custom manufacture molds for virtually any other machinery manufacturer in the industry,such as Tiger block machine,Hess Block Machine,Mass Block Machine,Zenith Block machine etc..Professional and Unique Heat Treatment The use of the advanced multi-functional heat treatment,all processes are controlled by the PLC, without any manual intervention, and the result of heat treatment is ensured from multiple angles.All Moulds are trearted by Carburizing, Nitriding and Quenching to guarantee the hardness of the mould core and tamper head plates to ensure long life time.Precision depends on details of each manufacturing process. High end processing equipments to ensure high precision and durability of moulds.Customers' ready moulds in workshop.Painting and Packing of ready moulds. Using seaworthy long distance transportation packing with pallet tray on bottom,packing straps and film wrapping.Different shapes of Concrete Products Moulds available based on customized manufacturing drawings.Our Contact

Send now