Building Material Brick Machinery Qt6

Building Material Brick Machinery QT6-15 Cement Block Making Machine Hollow Paver Solid Curbstone Molds Customized Featu

Description

Basic Info.

| Model NO. | QT6-15 |

| Vibration Force | 60 Kn |

| Host Machine Power | 29.85kw |

| Rated Pressure | 16 MPa |

| Workship Areas | 250-300m2 |

| Vibration Frequency | 2800-4500r/Min |

| Cycle Time | 15-25s |

| Mixer Model | Js 500 |

| Voltage | 220-440V |

| Processing Method | Hydraulic Pressure |

| Dimension | 3500X1700X2930mm |

| Pallet Size | 960X700mm |

| Productivity | 8640-10080 Pieces 40X20X20cm Blocks /8 Hours |

| Transport Package | Standard Export Packing |

| Specification | Q235B Jigang steel |

| Trademark | weda |

| Origin | China |

| HS Code | 8474802000 |

| Production Capacity | 120 Sets Brick Making Machine /Month |

Product Description

Features:

1) New design, simple structure, easy in installation and operation.2) High vibration ensure high density of the finished products, suitable for solid bricks and pavers. 3) Reasonable raw material ratio can produce high strength standard brick, after forming, can stack immediately.

Product Description

| Main technical parameter | ||||||||

| 1 | Dimension of host machine | 3500x1700x2930 | 6 | Host machine power | 29.85 kw | |||

| 2 | Weight of host machine | 8T | 7 | Vibration force | 60KN | |||

| 3 | Molding area | 861x880 | 8 | Mixer model | JS500 | |||

| 4 | Water consumption | 5-8Ton/day | 9 | Pallet size | 970/900x700x25mm | |||

| 5 | workshop area | 250-300m2 | 10 | Voltage | 380/415/440 | |||

| Theoretical production capacity | ||||||||

| No | Size(LxWxH) | Reference pic | Pcs/Mould | Pcs/Hour | Pcs/Shift | |||

| 1 | 400x200x200mm |

| 6 | 1080-1260 | 8640-10080 | |||

| 2 | 400x250x200mm |

| 4 | 720-840 | 5760-6720 | |||

| 3 | 230x110x70mm |

| 30 | 5400-6300 | 43200-50400 | |||

| 4 | 200x100x60 | 24 | 4320 | 34560 | ||||

| 5 | 200x163x60 | 16 | 2880 | 23040 | ||||

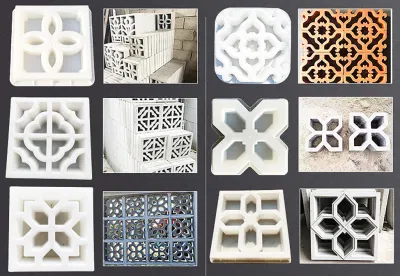

Block samples

Different shaps of colored Pavement Bricks, Cement hollows Blocks and solid brick with kerbstone blocksproduction by one machine only For the block production formula as followed just for reference :

- 8-10% cement, 30-40 % sand , 50-60% crushed stone.

- 8-10% cement, 30% flyash, 60% sand or stone powder

• The Block making machine product process is controlled by PLC and fitted with remote control device.for PLCcontrol system,we usually use Japan Mitsubishi or Germany Siemens Brand • The electricity motor for Cement Block Machine ,we use Germany Siemens motor ,for other parts ,we use CE motor .• about the switches ,we will use France brand or China CHNT

Cement Block Machine loading photos

Pavement Cement Block Machine in client production site

• Rakes in several rows make sure raw concrete materials fed well-distributed.• Hydraulic components we use Taiwan Yuken famous brands.• The demoulding synchronizer avoids the damage to cement blocks.• The vibration system for concrete kerbs contains two part ,one is up-moild vibbration box ,it is electricity motor to supply the power for up-mould vibration box. And the down mould ,there have one big vibration. when the scatter material work finish ,the hydraulic power with the two vibration force will assure the good density of Hollow Cement Block Machine,solid pavers blocks and concrete kerbs..etc

Shandong Weida Construction Machinery CO., Ltd is located in Linyi City, Shandong Province,China.With RMB 16 million investment and 53,000 square meters area, We are always developinggood and realiable Cement Block Machine, AAC block machine...etc with otherConstruction machinery with international standards to meet clients demands(people-oriented,leading technology, winning quality, and serving user ). We had exported to more than 100 countries.We have more than 60 technician to ensure superior installations and after sale service toassist clients to install the machine and perfrom the proper training abroad.

We warmly welcome customers from all over the world come to visit our factory and discusslong term cooperation.we are 24 hours service on you! Thank you !

Our Contact

Send now